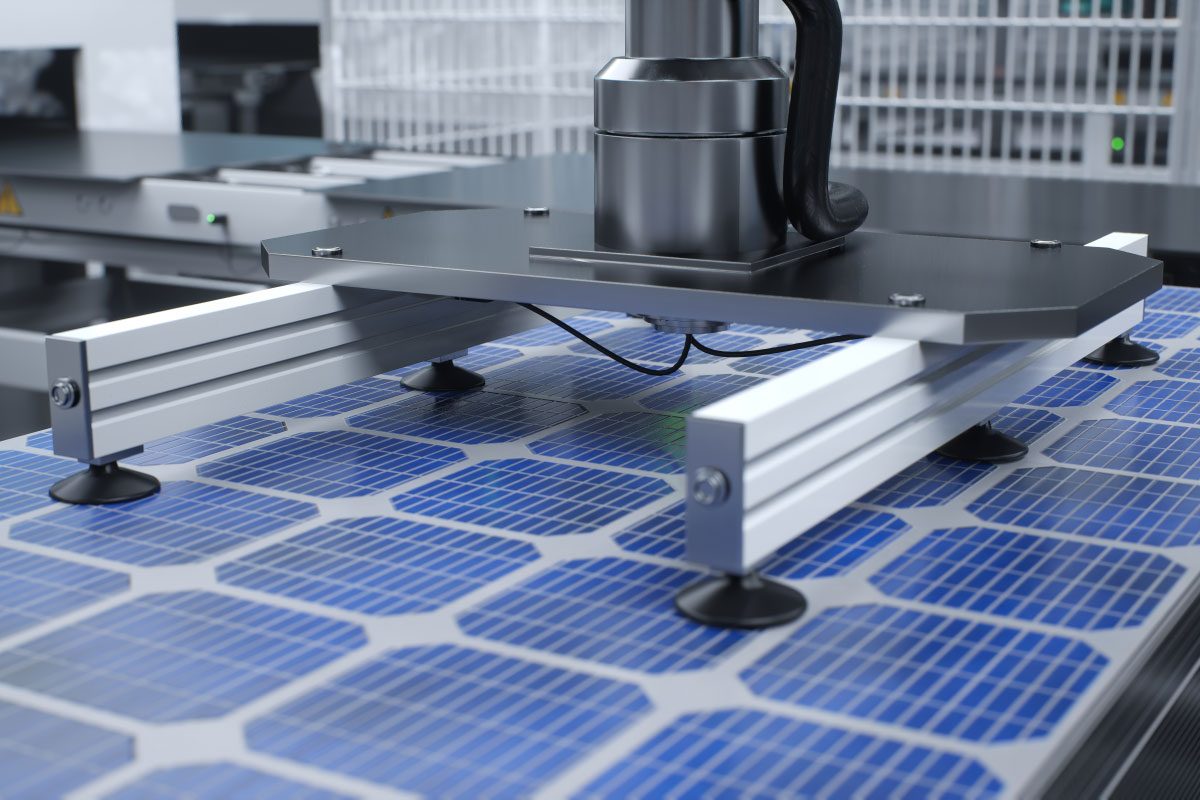

CNC (Computer Numerical Control) technology plays a key role in the production of photovoltaic systems. Precision numerical control makes it possible to produce high-quality components that are essential to the smooth operation of solar systems. CNC is used in the production of panel frames, mounting systems, inverters and other vital components of photovoltaic infrastructure.

Key advantages of CNC technology in the photovoltaic industry include:

- Precision machining, ensuring accurate dimensions and smooth surfaces,

- Repeatability of processes, ensuring consistent quality,

- Ability to adapt quickly to changing market requirements,

- Efficient use of materials, which reduces waste.

CNC machines, such as milling machines, lathes or laser and plasma cutting machines, enable the processing of a wide variety of materials, such as aluminum, stainless steel and plastics. Thanks to these devices, the production of components with complex shapes and high quality requirements becomes possible.

The use of CNC technology in production processes increases productivity and improves the quality of components, while reducing costs. This makes photovoltaic systems more competitive in terms of price and more reliable.

The development of CNC technology is having a significant impact on the energy transition and the development of renewable energy, supporting sustainability efforts. This cutting-edge approach is contributing to further progress in the photovoltaic industry.

Key applications of CNC milling in solar panel manufacturing

CNC milling is vital in the solar panel manufacturing process, ensuring the precise and efficient creation of key components.

The technology is used in a variety of areas:

Photovoltaic panel frames

CNC milling makes it possible to produce lightweight and durable aluminum frames that protect solar cells from mechanical damage and weather conditions. The precise fit of the panels to the frames improves heat dissipation, which increases the efficiency of the cells. The frames are often anodized, which increases their resistance to the elements.

Fastening systems

CNC technology makes it possible to create brackets and mounts that ensure the stability of solar panels on roofs and ground structures. Precisely positioned mounting holes facilitate installation and increase the durability of the entire system.

Solar tracking system components

CNC milling machines are used to manufacture components such as gears, shafts and mounting brackets used in solar tracking systems. Precision machining ensures that the mechanisms operate efficiently to maximize the use of solar energy.

Heat sinks and cooling elements

Advanced CNC milling allows the creation of heat sinks and heat exchangers used in inverters and other components of photovoltaic systems. Carefully molded cooling fins improve heat dissipation, increasing equipment efficiency.

Inverter housings

CNC milling is used in the production of solar inverter housings. Precision manufacturing enables perfect fit of electronic parts and effective protection against moisture and contamination.

The use of CNC milling in the production of solar panels contributes to improving their performance, durability and reliability. Precision in machining increases efficiency in the use of materials, lowers production costs, and makes it possible to offer more competitive prices in the renewable energy market.

CNC milling in creating components for solar tracking systems

Solar tracking systems, known as solar trackers, are crucial to increasing the efficiency of photovoltaic installations. CNC milling plays an important role in the production of components for these systems, ensuring high precision and reliability.

Mechanical components

CNC milling enables the creation of precision parts such as gears, shafts and bearings that support the smooth operation of solar trackers. Precise machining minimizes friction and wear, extending the life of the system. The ability to form complex shapes and structures sets CNC technology apart from other manufacturing methods.

Brackets and frames

CNC technology makes it possible to produce sturdy brackets and frames that stabilize solar panels in the correct position relative to the sun. Precision manufacturing ensures a perfect fit of the components and their resistance to mechanical loads and weather conditions. These properties guarantee reliable operation of the systems for many years.

Control systems

CNC milling is also used in the production of housings and components of solar tracker control systems. Precise machining ensures adequate protection of electronic components from moisture, dust and mechanical damage. High-quality workmanship translates into reliable operation of the entire system.

Performance optimization

CNC technology makes it possible to design advanced solar tracking system designs that increase the efficiency of photovoltaic panels. Trackers position panels at the optimal angle to the sun throughout the day, which can increase installation efficiency by 20-30% compared to static systems.

CNC milling plays a key role in manufacturing components for solar tracking systems. Precision machining creates advanced mechanical and electronic designs that support the reliability of solar trackers and extend their life. This technology plays a significant role in increasing the efficiency of photovoltaic installations, contributing to the development of renewable energy sources.

Impact of CNC milling on the performance and durability of solar installations

CNC milling plays a key role in increasing the energy efficiency and durability of solar installations. The technology enables precision manufacturing of components, which affects the long-term reliability of the systems.

Increased assembly precision

CNC milling allows assembly components to be manufactured with exceptional accuracy. Precise matching of components minimizes energy losses due to assembly imperfections. Accurately milled profiles and brackets ensure optimal alignment of the panels with the sun, which increases the amount of absorbed radiation.

Optimization of heat dissipation

CNC technology makes it possible to create advanced cooling systems for panels and inverters. Precision-made heat sinks and cooling channels dissipate heat more efficiently. Reducing the operating temperature of panels by as little as 1°C can improve their efficiency by 0.5%.

Improved weather resistance

Components made using CNC milling feature improved resistance to the elements. Careful surface treatment reduces the risk of corrosion and material degradation. Carefully made seals and connections prevent moisture and contaminants from penetrating the system.

Increased mechanical durability

CNC milling allows optimization of component shapes and structures. Precisely made load-bearing and mounting components better withstand loads caused by wind, snow or temperature changes. Such solutions extend the life of solar installations.

Reduction of energy losses

CNC milling makes it possible to create components with optimized geometry, which reduces energy losses in the system. Precision-made connectors and wires minimize resistance to current flow, increasing the efficiency of the installation.

Easier maintenance and service

Components manufactured using CNC milling are characterized by greater modularity and interchangeability. This makes maintenance and repair of solar installations easier, reducing maintenance costs and increasing uptime.

The use of CNC milling in the production of solar installations significantly affects their performance and durability. Precision manufacturing, optimized design and increased resistance to external factors contribute to better energy efficiency and longer service life. These features make photovoltaic installations more cost-effective and competitive with traditional energy sources.

Impact of CNC milling on the performance and durability of photovoltaic installations

CNC milling plays an important role in improving the performance and durability of photovoltaic installations. It is possible to achieve high energy efficiency and reliability for years of use.

Improved assembly precision

CNC milling ensures the production of photovoltaic panel mounting components with extreme accuracy.

Precise matching of components:

- Reduces energy losses due to inaccurate assembly.

- Promotes optimal alignment of panels with the sun, maximizing radiation absorption.

- Ensures durability and reliability of mounting structures.

Optimizes heat dissipation

Cooling systems created with CNC milling efficiently dissipate heat from panels and inverters. P

recycled heat sinks and cooling channels:

- Lower the operating temperature of the panels, which increases their efficiency.

- They improve the efficiency of photovoltaic cells, reducing the risk of overheating.

Every 1°C less in panel temperature increases system efficiency by up to 0.5%.

Improved weather resistance

Components made using CNC milling are distinguished by their high resistance to weathering.

Main benefits:

- Reduced risk of corrosion due to smooth surfaces and robust seals.

- Protection against moisture and contamination thanks to durable connections.

Mechanical durability and reduced energy loss

CNC milling optimizes component shapes and structures, which:

- Increases the mechanical durability of load-bearing and fastening components.

- Reduces resistance to current flow in connectors and wires, which increases the efficiency of the photovoltaic system.

Easier maintenance and service

Photovoltaic system components are modular and easy to replace.

- Simplifies maintenance,

- Reduces maintenance costs,

- Increases uptime.

The use of CNC milling in the photovoltaic industry makes it possible to achieve higher energy efficiency, greater durability of systems and their resistance to harsh outdoor conditions. Installations become more cost-effective, competitive and suitable for long-term use.

CNC milling in the production of components for photovoltaic roof tiles

CNC milling plays a key role in the production of photovoltaic roof tiles, enabling the creation of precise and durable components. The technology makes it possible to produce components with complex shapes and high accuracy. This is crucial for the efficient operation and aesthetic appearance of solar roof tiles.

Photovoltaic cell housings

CNC milling machines are used to produce accurate housings for photovoltaic cells embedded in roof tiles. Precision machining ensures that the cells fit perfectly into the housings, which increases light absorption and protects the delicate components from the elements.

Mounting systems

CNC makes it possible to create advanced fastening systems that connect photovoltaic tiles to conventional roofing. Precision milling ensures tight connections and stability of the entire structure.

Cooling channels

CNC milling makes it possible to create complex cooling channels in the structure of solar roof tiles. The optimal geometry of these channels promotes efficient heat dissipation, which contributes to higher efficiency of photovoltaic cells.

Connecting elements

CNC technology makes it possible to produce accurate connecting components that integrate individual solar tiles into a coherent system. The precision of these components guarantees the tightness of the roofing and proper electrical connections between modules.

The use of CNC milling in the production of photovoltaic roof tiles increases their performance, durability and aesthetics. The accuracy of machining allows better use of roof space and full integration of the photovoltaic system into the architecture of the building. Solar roof tiles thus become an attractive solution that combines the function of roofing with clean energy production.

CNC milling in the production of energy storage systems for photovoltaics

CNC milling plays an important role in the development of energy storage systems for photovoltaics. This technology allows for increased performance and safety of these systems.

Battery housings

CNC makes it possible to accurately manufacture battery enclosures that must meet strict safety requirements. Precision machining ensures resistance to high temperatures and pressure, which guarantees safe energy storage.

Cooling systems

CNC milling makes it possible to create advanced cooling systems with optimized designs. Carefully crafted heat sinks and cooling channels improve heat dissipation. This leads to higher performance and longer life for energy storage systems.

Connecting components

CNC technology enables the production of precision connectors and couplers. These provide secure electrical connections between battery modules. The precision manufacturing minimizes the risk of failure and potential hazards.

Energy management components

CNC is used in the production of energy management system components, such as heat sinks for electronic circuits and controller housings. Precision machining supports the efficient operation of key components.

The use of CNC milling in the production of energy storage systems for photovoltaics increases their reliability, safety and performance. The accuracy of machining helps optimize the design, resulting in better space utilization and more efficient energy management in photovoltaic installations.

The role of CNC milling in the development of smart solar energy management systems

CNC m illing plays a key role in the manufacture of components for smart solar energy management systems. The technology enhances the performance and reliability of these systems.

Precise controller housings

CNC technology makes it possible to create precise housings for controllers that manage energy flow in photovoltaic systems. Precision machining protects the electronics from external influences, extending the life of the devices.

Cooling system components

CNC milling makes it possible to produce intricate heat sinks and cooling channels for electronic components. The refined geometry of these components supports efficient heat dissipation, which ensures stable circuit operation.

User interface components

CNC enables the production of precision control panel components and displays. These components, which are an integral part of energy management systems, are distinguished by their ergonomics and durability.

Connecting components

CNC milling is used in the production of precise connectors and couplers. They provide reliable connections between energy management system modules, which increases their functionality and safety.

The use of CNC milling in the creation of components for smart solar energy management systems improves their performance, durability and reliability. Precision machining allows for design optimization, which supports efficient energy management in photovoltaic systems.

Using CNC to manufacture precision parts for solar inverters

Solar inverters are an essential component of photovoltaic systems, as they convert direct current from the panels into alternating current used in electrical grids. CNC milling plays a key role in the production of precision parts for inverters, affecting their performance and reliability.

Inverter housings

CNC enables the creation of precision enclosures that protect electronic components from mechanical damage and environmental influences. The airtightness and resilience provided by precision machining are key to the long life of the equipment.

Heat sinks and cooling systems

CNC milling makes it possible to:

- Producing heat sinks with optimized geometries.

- Creating cooling channels that support efficient heat dissipation.

Such solutions guarantee stable operation of inverters in harsh environments.

Electronic circuit components

CNC is used to manufacture:

- Printed circuit boards that ensure reliable connections between components.

- Precision connectors that minimize the risk of failure and improve the durability of devices.

Connectors and connectors

Precision CNC milling produces connectors and connectors that provide:

- Secure electrical connections between modules.

- High reliability of the entire system.

CNC technology in the production of components for solar inverters contributes to improving their durability, performance and functionality. Precision machining improves the efficiency of the devices and promotes the optimal use of solar energy in households and industry.

Materials used in CNC machining for the photovoltaic industry

In the photovoltaic industry, selecting the right materials for CNC machining is crucial. It ensures the durability, performance and reliability of components that must meet high mechanical, thermal and chemical requirements.

Aluminum

Aluminum is one of the most widely used materials in the photovoltaic industry. It is characterized by:

- Lightweight, which makes it easy to install and transport.

- Resistance to corrosion, which increases durability.

- Good thermal conductivity, important for heat sinks and inverter housings.

CNC milling allows precise shaping of aluminum, which optimizes the design of panels and other components.

Stainless steel

Stainless steel is used in structural and assembly components. Its characteristics, such as strength and resistance to harsh weather conditions, make it indispensable in solar systems. CNC milling can be used to achieve intricate shapes that increase the durability of components.

Plastics

Plastics are used in the production of lightweight and weather-resistant components, such as controller housings and insulation components. CNC milling:

- Provides airtightness, which protects against moisture.

- Guarantees electrical insulation, important for system safety.

Copper

Copper is crucial in the manufacture of conductors and connectors. It has excellent electrical conductivity, which makes it applicable to photovoltaic systems. Precise CNC shaping of copper allows for efficient current flow and minimized losses.

Composites

Composites are valued for their light weight and high strength. CNC milling makes it possible to create advanced structures that combine features of different materials. As a result, components become more efficient and durable.

The selection of materials for CNC machining in the photovoltaic industry is extremely important. Precise machining allows for the optimization of the structure, which translates into high energy efficiency and reliability of the installation over the long term.

Economic benefits of using CNC technology in photovoltaics

The use of CNC technology in the production of photovoltaic components brings significant economic benefits that support the competitiveness and development of the entire industry.

Reduction of production costs

CNC milling automates manufacturing processes, which significantly reduces labor costs. Precision machining minimizes material waste, leading to raw material savings. The introduction of CNC in production can reduce costs by 20-30% compared to traditional methods.

Increase production efficiency

CNC technology makes it possible to produce large quantities of components quickly and accurately.

- Machines operate around the clock, increasing productivity.

- A 40-60% reduction in production time compared to conventional methods translates into faster order fulfillment.

Improved quality and reduced scrap rates

High precision CNC machining ensures better quality of final products. The reduction in the number of defects can reach up to 80%. Fewer defective parts means lower costs and improved profitability.

Production flexibility

CNC makes it possible to quickly adapt production processes to changing market needs.

- The ease of modifying machiningprograms allows you to make design changes without costly downtime.

- The ability to produce different parts on the same production line supports operational flexibility.

Optimization of material usage

Advanced CNC software allows efficient use of materials, minimizing waste.

- In the photovoltaic industry, where expensive raw materials are used, savings can amount to 15-20%.

Reduce time to introduce new products

CNC technology speeds up prototyping and testing of new solutions.

- The time from design to finished product can be reduced by up to 50%.

- Bringing new products to market faster increases the competitive advantage of companies.

The use of CNC technology in photovoltaics brings specific benefits, such as:

- Reduction of production costs,

- Improved product quality,

- Increased competitiveness of companies.

As a result, photovoltaic systems are becoming more affordable, supporting the development of renewable energy and the global energy transition.

Summary

CNC technology plays an important role in the development of the photovoltaic industry, covering the production of solar panels, solar tracking and energy management systems. The high precision and efficiency of CNC milling allows the creation of durable and high-quality components, which affects the reliability of solar installations. The optimization of machining processes and the use of suitable materials increase production efficiency and improve the competitiveness of companies in the market.

Automation of production processes by CNC machines significantly reduces labor costs and material waste. Precise planning and execution of machining allow maximum utilization of raw materials, which is especially important in an industry that uses expensive materials. CNC milling makes it possible to produce a large number of parts quickly and accurately, significantly reducing lead times. Thanks to this approach, the quality of final products remains high and the number of production shortages is minimal.

The flexibility provided by CNC technology makes it easy to adapt production processes to current market needs. The ability to modify designs without costly changes to production lines increases productivity and allows faster response to changing customer requirements. Advanced CNC machining management software optimizes processes, helping to reduce material losses and lower production costs.

In the context of environmental and sustainability efforts, CNC technology supports the creation of green solutions in renewable energy. The production of components with high durability and efficiency reduces the need for frequent replacements, which reduces the environmental impact. In addition, the ability to rapidly prototype and test new solutions reduces time-to-market, making companies more competitive.

CNC milling supports the global energy transition, enabling the creation of photovoltaic systems to meet growing market demands. Precision machining ensures the durability and efficiency of components, which affects the availability and cost-effectiveness of renewable energy. This approach contributes to the development of green energy sources and supports efforts to reduce CO2 emissions.

Sources:

- https://www.violintec.com/precision-machining/importance-and-applications-of-cnc-milling-in-the-renewable-energy-sector/

- https://www.dekmake.com/cnc-machining-for-renewable-energy-parts/

- https://g2voptics.com/photovoltaics-solar-cells/solar-cell-materials/

- https://cncpartsxtj.com/cnc-machining/cnc-machine-tools/how-dose-cnc-machining-drives-innovation-in-renewable-energy/

- https://www.rapiddirect.com/blog/cnc-machining-for-green-energy-industry/

- https://at-machining.com/cnc-machining-renewable-energy/