Metalworking is a key process in the manufacturing industry, which has evolved significantly thanks to modern technology. A comparison of the efficiency and quality of CNC (Computer Numerical Control) metalworking with traditional techniques shows clear differences in precision, productivity and production capabilities.

CNC machining uses advanced machine control software to achieve remarkable accuracy, often at the micrometer level. Such precision translates into higher quality end products and less material consumption. Traditional methods, while valued in certain applications, are more prone to human error and have limited repeatability.

Production efficiency is higher with CNC, especially for large batches. CNC machines run continuously, performing complex operations without human intervention. Traditional methods, on the other hand, require the constant presence of experienced operators, which limits efficiency and increases costs.

The decision between CNC and traditional techniques depends on project requirements, the level of precision needed and the scale of production. CNC machining dominates modern industry, but traditional techniques are still used for unit production and specialized projects.

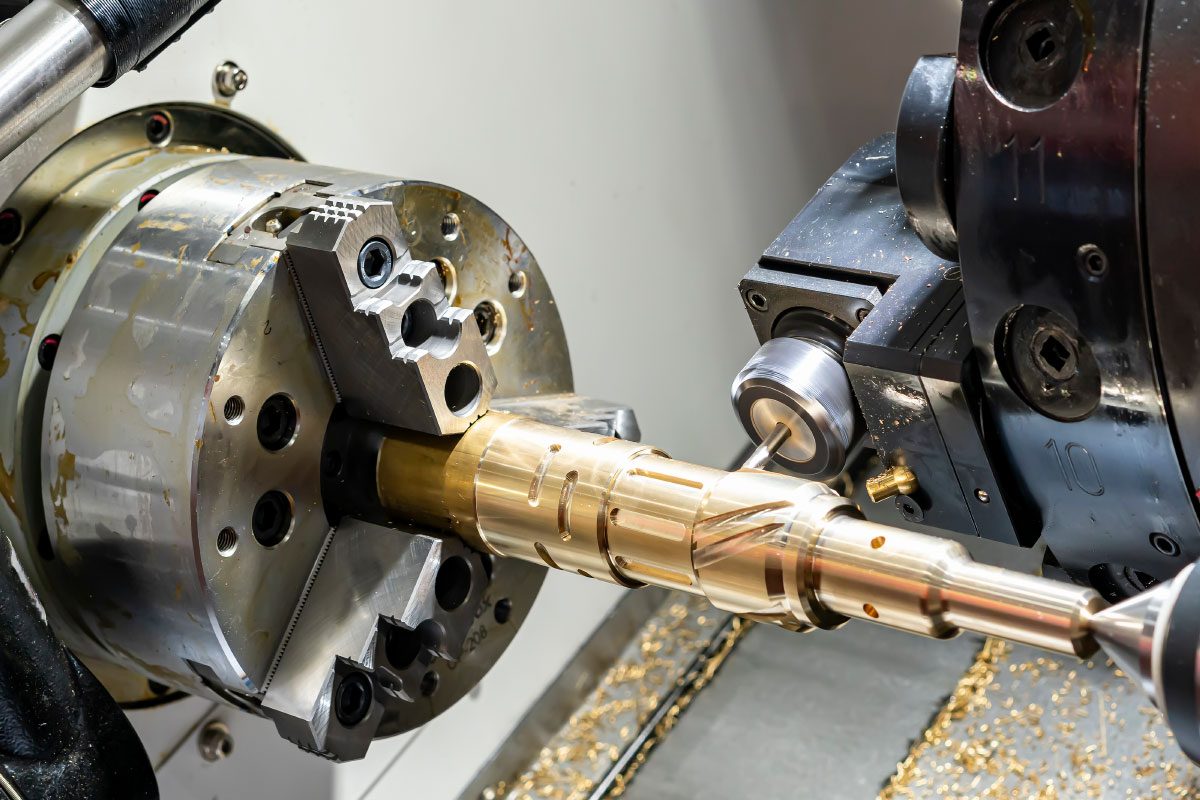

How does CNC machining differ from traditional metalworking methods?

CNC machining and traditional metalworking techniques differ fundamentally in their approach to material shaping. The main difference lies in the degree of automation and precision manufacturing.

CNC machining uses advanced computer software to control machines. The process begins with the creation of a three-dimensional model of the part in CAD (Computer-Aided Design) software. The model is then converted into machine code that controls the movement of the cutting tools. CNC machines, such as milling machines, lathes and machining centers, perform precise movements according to programmed instructions.

Traditional techniques rely mainly on manual operator skills and mechanical tools. They include CNC turning, CNC milling, CNC drilling and CNC grinding, performed on conventional machine tools. The precision and quality of machining here largely depend on the operator’s experience.

Key differences between CNC machining and conventional methods:

- Automation: CNC machines operate autonomously once programmed, while traditional techniques require constant operator supervision.

- Precision: CNC offers higher accuracy and repeatability, often in the micrometer range. Traditional techniques are more susceptible to human error.

- Complexity: CNC enables the creation of complex shapes and geometries that are difficult or even impossible to produce with traditional methods.

- Efficiency: CNC machines can run continuously, which increases production efficiency. Traditional methods limit operator capacity.

- Programming: CNC requires knowledge of programming and operation of specialized software, while traditional methods rely on manual skills.

- Initial cost: CNC machines are more expensive to purchase than conventional machine tools.

- Flexibility: Traditional techniques are more flexible for small production runs or unique projects. CNC more efficient for large series.

- Preparation time: CNC machines may take longer to program initially, but subsequent production is faster. In traditional methods, preparation is shorter, but production itself takes longer.

CNC machining has revolutionized the metal industry, making it possible to produce parts of unprecedented precision and complexity. However, traditional machining methods still have their place, especially in small workshops and unit production.

Professor Jan Kowalski, an expert in manufacturing engineering

The choice between CNC and traditional methods depends on a number of factors, such as the scale of production, the precision required, the available budget and the specifics of the parts being produced. Both approaches have their advantages and are applicable in today’s metal industry.

Impact of automation on production efficiency in CNC machining and conventional methods.

Automation plays a key role in increasing production efficiency – both in CNC machining and conventional techniques. However, the scale and scope of automation differ significantly between these approaches.

In CNC machining, automation is an integral part of the process. CNC machines are computer-controlled, which allows for:

- Continuous operation without interruption, often around the clock,

- Perform complex operations without the need for human intervention,

- Quick switching between different production tasks,

- Integration with production management and quality control systems.

Automation in CNC machining not only increases productivity, but also significantly reduces the risk of human error, which translates into higher quality final products.

Professor Anna Nowak, an expert in manufacturing engineering

In conventional methods, the level of automation is usually lower. Traditional machine tools require constant operator presence and manual intervention. Nonetheless, modern manufacturing plants are introducing elements of automation into conventional machining methods as well, such as:

- Semi-automatic material feeding systems,

- Automatic measuring systems,

- Digital displays of machining parameters.

Comparison of the impact of automation on production efficiency:

| Aspect | CNC machining | Conventional methods |

|---|---|---|

| Working time | 24/7 | Limited by operator working time |

| Precision | High, constant | Variable, dependent on operator |

| Complexity of operations | Very high | Limited |

| Flexibility of production | High | Medium |

| Initial costs | High | Lower |

Automation in CNC machining has a significant impact on production efficiency, especially for large runs. CNC machines can run continuously, performing complex operations with high precision and repeatability.

In conventional methods, although the level of automation is lower, there are ways to improve efficiency by:

- Optimizing work processes,

- Training of operators,

- Implementing quality control systems.

Automation has a much stronger impact on production efficiency in CNC machining than in conventional techniques. However, both approaches can be optimized to increase efficiency. The choice between the two depends on the specifics of production, quality requirements and the scale of operations.

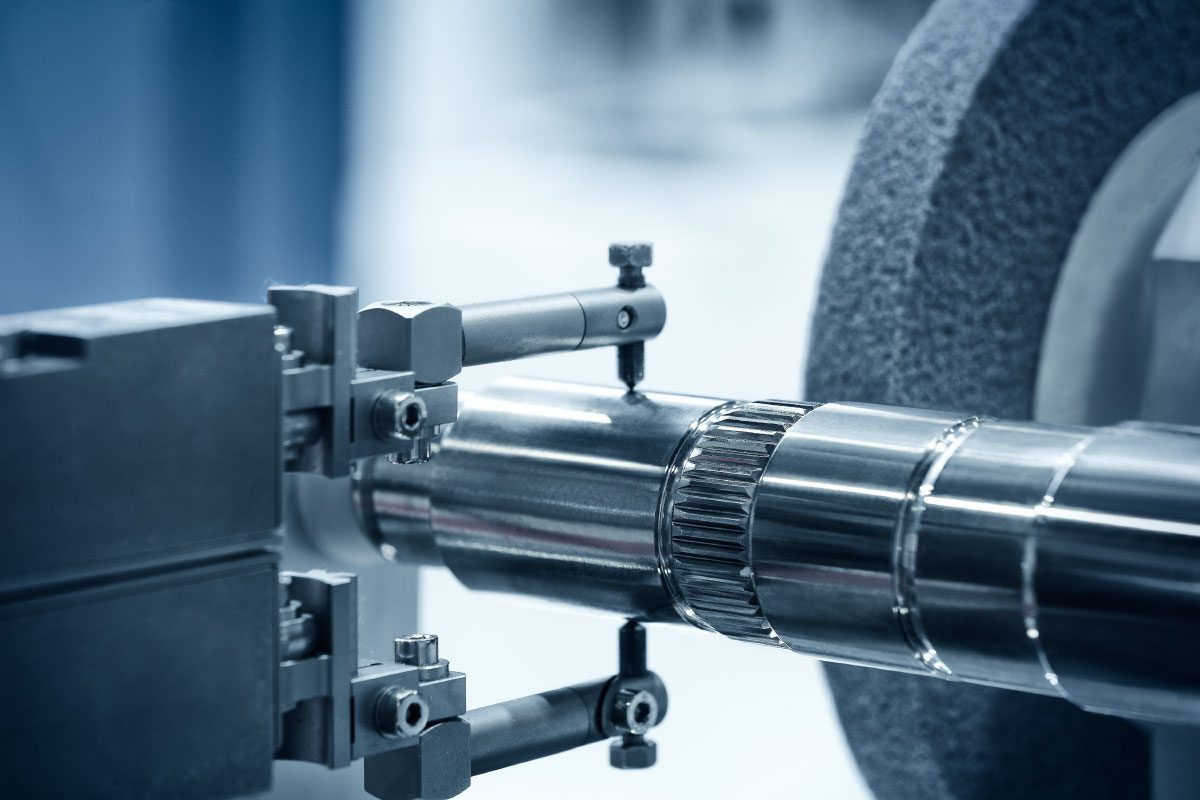

Comparison of precision and repeatability of results in CNC machining and traditional methods.

Precision and repeatability are key aspects in industrial manufacturing. The differences between CNC machining and traditional techniques in these areas are significant.

Precision of CNC machining

CNC machining provides unparalleled precision thanks to computer control and advanced positioning systems. CNC machines can achieve tolerances on the order of micrometers, which traditional methods find difficult or even impossible to achieve.

Data from Rapid Direct indicates that the typical accuracy of CNC machines is between 0.0002 and 0.0005 inches (about 0.005 to 0.013 mm). Such precision is essential in industries like aerospace, medicine and electronics, where even minimal deviations can have serious consequences.

Repeatability in CNC machining

Repeatability means the ability to consistently reproduce the same results. In this area, CNC machining is superior to traditional methods. Industrial CNC machines, such as laser cutters, achieve repeatability of ±0.0005 inches (about ±0.013 mm).

This high repeatability is due to the fact that CNC machines precisely execute programmed instructions every time, eliminating variability due to human operators.

Precision and repeatability in traditional machining

Traditional methods, although they can achieve high precision in the hands of experienced operators, are more susceptible to variability and human error. Accuracy and repeatability here depend heavily on operator skill and experience.

Even the most experienced operators can make mistakes, leading to differences in accuracy from one component to another. In batch or mass production, such variability can be a problem.

Comparison of precision and repeatability:

| Aspect | CNC machining | Traditional machining |

|---|---|---|

| Precision | 0.0002-0.0005 in | Variable, operator dependent |

| Repeatability | ±0.0005 in | Lower, operator dependent |

| Stability of results | High | Variable |

| Human factor influence | Minimal | Significant |

Impact on production quality

Higher precision and repeatability of CNC machining contributes to:

- Reducing scrap and production waste,

- Achieving higher quality of the final product,

- The ability to produce complex parts with high accuracy,

- Facilitating quality control at every stage of production.

CNC machining offers much higher precision and repeatability than traditional methods. This is crucial in modern industrial manufacturing, especially in industries requiring the highest accuracy.

Lead time: CNC machining versus conventional methods

Lead time is a key factor affecting production efficiency. In this aspect, CNC machining offers a significant advantage over conventional methods.

CNC machining

CNC machining is characterized by shorter lead times compared to conventional methods:

- Speed of operation: CNC machines run at a higher speed than conventional machine tools, which reduces machining time.

- Continuous operation: CNC machine tools run continuously for long periods of time, often 24/7.

- Process automation: Once programmed, the machine performs repetitive operations without interruption and without the need for operator intervention.

- Quick changeover: Changing the type of part being produced requires only a program change, which takes only a few minutes.

Conventional methods

Conventional machining methods are characterized by longer job completion times:

- Manual operation: Each operation requires an operator, which increases production time.

- Physical limitations: Speed and precision depend on the physical capabilities of the operator.

- Work interruptions: Operators need breaks, which increases total production time.

- Time-consuming changeovers: Changing the type of part being produced often requires manual changes to machine settings, which is time-consuming.

Time efficiency comparison

CNC machining is much more time-efficient than conventional methods:

- Batch production: When producing large series of parts, CNC can be up to several times faster than conventional methods.

- Complex parts: In the production of complex parts, the difference in lead time in favor of CNC can be even greater.

- Repeatability: CNC ensures consistent quality and production rates, whereas in conventional methods, operator productivity can decline over time.

CNC machining allows for much shorter lead times than conventional methods, resulting in higher production efficiency and shorter lead times. This is especially important in batch production and when manufacturing complex parts.

The role of the operator in CNC and conventional machining processes

The role of the operator in CNC machining and traditional methods differs significantly, due to the different specifications of these processes.

The role of the operator in CNC machining

In CNC machining, the role of the operator has changed significantly compared to traditional methods:

- Programming: The CNC operator needs machine programming skills, often using languages like G-code or specialized CAM software.

- Process supervision: The operator monitors the operation of the machine and intervenes only when necessary, rather than directly controlling the machine.

- Quality control: The operator is responsible for the quality of the parts produced, often using sophisticated measurement systems.

- Process optimization: Constantly improving the production process, analyzing data and making improvements are the operator’s main tasks.

- Operating multiple machines: Thanks to automation, a single operator can oversee the operation of several CNC machines simultaneously.

The operator’s role in traditional machining

In traditional machining, the operator’s role is more direct:

- Manual control: The operator controls tool movements and machining parameters manually.

- Experience and skill: The success of machining depends largely on the operator’s knowledge and practice.

- Limited efficiency: The operator operates one machine at a time, which affects overall production efficiency.

- Greater risk of errors: Due to direct human involvement, the risk of errors in the machining process is higher.

Changes in operator skills

The development of CNC technology requires new skills for operators:

- Software knowledge: CNC operators must be proficient with specialized machine programming software.

- Analytical skills: Analyzing process data and optimizing production become key.

- Flexibility: Operators must constantly evolve and adapt to new technologies.

The operator’s role in CNC machining has evolved from direct machine control to more advanced tasks of programming, supervising and optimizing processes. It now requires a wider range of technical and analytical skills compared to traditional machining methods.

Cost analysis of implementing and operating CNC machines and traditional machine tools

Implementing CNC technology and operating CNC machines involve different costs than traditional machine tools. Understanding these differences allows you to better evaluate the economic aspects of both solutions.

Initial costs

CNC machines have higher initial costs:

- Purchasing aCNC machine is usually several times more expensive than purchasing a traditional machine tool.

- An investment in specialized CAD/CAM software is required.

- Employee training on new machines and software is required.

Traditional machine tools have lower initial costs:

- Lower machine purchase price.

- No investment in advanced software required.

- Lower training requirements for operators.

Operating costs

Over the long term, CNC machines can be more economical:

- Higher production efficiency lowers unit costs.

- Less material consumption through precision machining and process optimization.

- One operator can operate several CNC machines simultaneously.

Traditional machine tools generate higher operating costs:

- Lower production efficiency.

- Higher material consumption due to more waste.

- The need to hire more skilled operators.

Maintenance costs

CNC machines require specialized maintenance:

- Higher maintenance costs due to advanced electronics.

- Need for regular software updates.

Traditional machine tools are easier to maintain:

- Lower repair and maintenance costs.

- No costs associated with software updates.

Cost effectiveness

The choice between CNC technology and traditional machine tools depends on the specifics of production:

- In the production of large series and complex parts, CNC machines are more cost-effective in the long run.

- For small series or simple parts, traditional machine tools may be more economical.

CNC machining, despite higher initial costs, often proves more cost-effective in the long run, especially for companies producing large series of complex parts. However, in smaller workshops or when producing simpler parts, traditional machine tools can still be a good choice.

Comparison of implementation and operating costs:

| Aspect | CNC machines | Traditional machine tools |

| Initial costs | Higher purchase costs; specialized CAD/CAM software required; training for employees | Lower purchase costs; no need for advanced software; less training required |

| Operating costs | Higher production efficiency; lower unit costs; lower material consumption; ability for one operator to operate several machines | Lower productivity; higher material consumption due to more waste; need for more operators |

| Maintenance costs | Higher maintenance costs due to advanced electronics; need for regular software updates | Lower repair and maintenance costs; no costs associated with software updates |

| Cost effectiveness | More cost-effective for large production runs and complex parts in the long run | More cost-effective for small production runs and simple parts |

Production capabilities of CNC and conventional machines in various industries

CNC machines and conventional machine tools are used in a wide range of industries, although their production capabilities differ significantly. When analyzed in the context of different industries, these differences help to understand the advantages and limitations of both technologies.

Aerospace industry

CNC machines:

- Manufacturing complex parts with high precision, such as turbine blades.

- Machining advanced materials such as titanium alloys and composites.

- Creating parts with complex geometries crucial to aerodynamics.

Conventional machine tools:

- Limited use, mainly for simple parts or repairs.

- Used in smaller workshops to produce custom parts.

Automotive industry

CNC machines:

- Mass production of precision parts for engines, transmissions, brake systems.

- Rapid adaptation to changes in vehicle designs and models.

- High repeatability, crucial to maintaining quality standards.

Conventional machine tools:

- Production of simple spare parts.

- Use in small repair shops.

Medical industry

CNC machines:

- Production of implants and prostheses with complex shapes.

- Production of precision surgical instruments.

- Ability to work with biocompatible materials.

Conventional machine tools:

- Limited use for simple medical tools.

- Used in small laboratories for prototyping.

Electronics industry

CNC machines:

- Manufacturing precision enclosures and heat sinks.

- Manufacturing molds for plastic components.

- Machining of printed circuit boards.

Conventional machine tools:

- Limited use due to the precision required.

- Used in prototyping and small batch production.

Oil and gas industry

CNC machines:

- Production of large, complex parts for drilling equipment.

- Machining of corrosion-resistant and high-pressure parts.

Conventional machine tools:

- Production of simple spare parts.

- Use in equipment repair and maintenance.

Jewelry industry

CNC machines:

- Precision machining of precious metals.

- Creation of complex designs and engravings.

- Repeatable production of identical components.

Conventional machine tools:

- Widely used due to tradition and unique skills of craftsmen.

- Production of unique, handcrafted products.

CNC machines dominate in industries where high precision, repeatability and the ability to create complex shapes are important. They are indispensable in mass production and in places where compliance with strict standards is necessary. Conventional machine tools are still used in smaller workshops, in unit production and in industries that value traditional methods.

Quality of the final product: CNC machining vs. traditional methods

The quality of the final product is a key factor in industrial production. CNC machining and traditional methods offer different possibilities in this area.

CNC machining

CNC machining is distinguished by features that affect product quality:

- High precision: CNC machines can achieve tolerances on the order of micrometers, which is difficult to achieve with traditional methods.

- Repeatability: CNC ensures consistent quality and identical parameters for each part, which is crucial in mass production.

- Complex shapes: The ability to create complex geometries that would be difficult or impossible to manufacture by hand.

- Surface smoothness: CNC allows for very smooth surfaces that require minimal finishing.

- Minimization of errors: Eliminating the human factor in the manufacturing process reduces the risk of errors.

Traditional methods

Traditional methods have their own distinctive advantages:

- Flexibility: Ease of customization for individual, non-standard orders.

- Craftsmanship: Ability to use the unique skills of experienced operators.

- Lower costs for small runs: Cost-effective for producing single parts or small batches.

- Limited precision: Difficulty in maintaining consistent quality with larger batches.

- Greater risk of errors: Dependent on operator skill and concentration.

Final quality comparison:

| Aspect of quality | CNC machining | Traditional methods |

|---|---|---|

| Precision | Very high | Variable |

| Repeatability | Excellent | Limited |

| Shape complexity | Unlimited | Limited |

| Surface smoothness | High | Variable |

| Production flexibility | High for large series | High for small series |

CNC machining offers higher end quality due to precision, repeatability and the ability to create complex shapes. It is ideal for batch production and parts requiring high accuracy. Traditional methods still lead the way in unit production, where flexibility and operator craftsmanship are key.

The future of metalworking: CNC technology vs. traditional methods

The future of metalworking is the subject of much discussion in the industry. Although CNC technology has revolutionized manufacturing, it will not completely displace traditional methods.

CNC dominance in industry

CNC machining will continue to gain in importance:

- Increasing automation: Integration with robotic systems and artificial intelligence will increase productivity and precision.

- Software development: Advanced CAD/CAM programs will enable even more complex operations.

- Industry 4.0: CNC will become a key component of the smart factories of the future.

Niches for traditional methods

Traditional machining methods will retain their position in some areas:

- Arts and crafts: Hand machining will be valued in the production of unique products.

- Small workshops: In small businesses, traditional methods may be more profitable.

- Repair and maintenance: In many cases, traditional methods will be more practical.

Hybrid approach

The future will likely bring hybrid solutions:

- Combining technologies: Integrating CNC with traditional techniques for best results.

- Flexible production lines: The ability to quickly switch between CNC and traditional methods as needed.

- Education and training: Educating professionals to combine CNC skills with traditional craftsmanship.

Summary

Comparing the efficiency and quality of CNC machining with traditional methods reveals significant differences. CNC provides high precision, repeatability and the ability to create complex shapes, making it ideal for mass production and parts requiring the highest accuracy. Traditional methods, while less precise, retain their value in unit production, where flexibility and craftsmanship count.

Key findings:

- Precision and repeatability: CNC significantly outperforms traditional methods.

- Production efficiency: CNC is more efficient for large runs; traditional methods perform better for small runs.

- Role of the operator: In CNC, the operator focuses on programming and supervision; in traditional methods, the operator focuses on direct machining.

- Costs: CNC requires a larger initial investment, but offers lower unit costs at large scale.

- The future: CNC will dominate, but traditional methods will retain niches.

The choice between CNC and traditional methods depends on the specifics of production, quality requirements and scale of operations. The future will most likely bring hybrid solutions that combine the advantages of both approaches.

Sources:

- https://www.autodesk.com/products/fusion-360/blog/cnc-machining-vs-traditional-machining/

- https://www.thomasnet.com/articles/custom-manufacturing-fabricating/cnc-machining-vs-conventional-machining/

- https://www.protolabs.com/resources/blog/cnc-machining-vs-conventional-machining/

- https://www.manufacturingtomorrow.com/article/2023/05/cnc-machining-vs-traditional-machining-which-is-better/20022

- https://www.3erp.com/blog/cnc-machining-vs-conventional-machining/