As a CNC PARTNER, we are a group of new technology enthusiasts who bring innovations in machining every day. Our story began with the merger of two companies with one common vision: to transform traditional machining into something unique, using modern methods such as milling, turning and EDM cutting. This is how our company was born, where the pursuit of innovation is our daily routine.

In our article, we will talk about our innovative machines, advanced manufacturing processes and, most importantly, our individual approach to each project. Our work is more than just a duty – it’s our mission to transform the world of machining by providing our customers with solutions that set industry standards.

CNC PARTNER Services: Complete Solutions in CNC Milling, Turning and Cutting

Since our inception, we have focused on developing our machinery and improving our machining processes. Our development has been a continuous evolution, from milling and turning to EDM cutting and advanced numerical control technologies. We are proud of our contribution to the development of CNC technology, which was recognized with an innovation award at the International Gas Forum in Warsaw in 2006. This award is proof to us that our approach to innovation is the right one.

At CNC PARTNER, we offer a wide range of CNC services that are tailored to the diverse needs of our customers. Our services include:

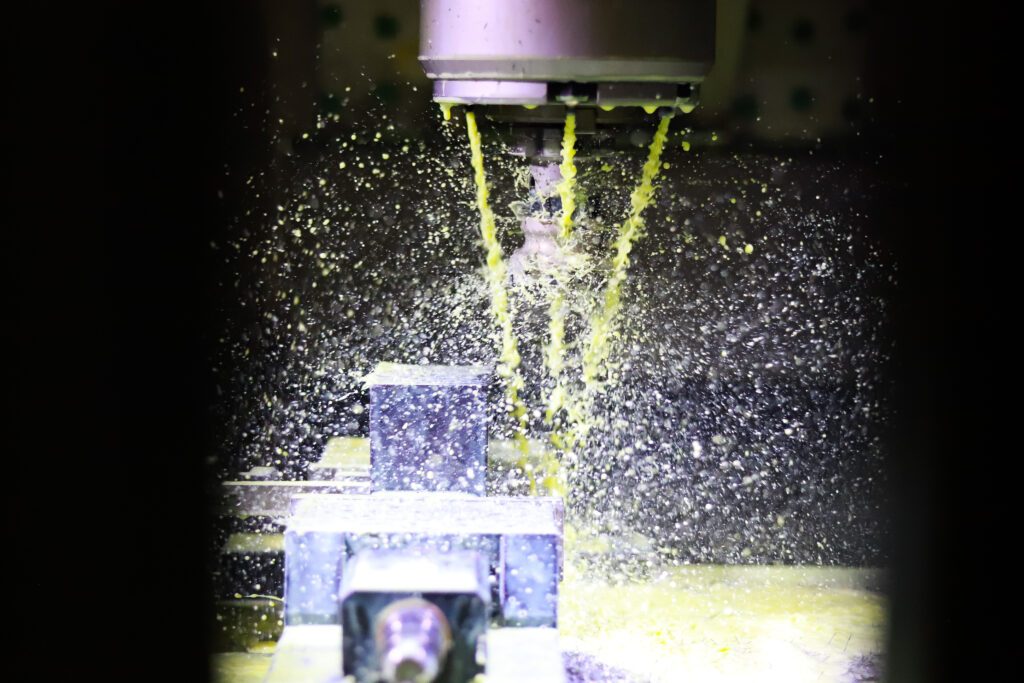

- CNC milling: We use advanced CNC milling techniques for precision machining of parts, offering the ability to create complex geometries and high-quality surface finishes.

- Electrical Discharge Cutting: This method allows us to process difficult-to-machine materials and realize complex shapes, which is crucial in the production of precision components.

- CNC turning: We specialize in CNC turning, which enables us to produce parts of high complexity and excellent dimensional precision.

- Plane grinding: We offer plane grinding to achieve smoothness and critical dimensions, which is essential for many engineering applications.

As part of our offerings, we utilize different types of CNC lathes, each bringing its own specific benefits:

- Claw lathes: Ideal for universal applications, they offer a wide range of machining.

- Chuck lathes: Excellent for machining irregularly shaped or large-diameter workpieces.

- Multi-blade lathes: Allow large quantities of similarly shaped parts to be machined, increasing production efficiency.

- Turret lathes: Allow quick tool changes, ideal for parts requiring multiple machining operations.

- Disc lathes: Excellent for machining large parts with simple shapes.

- Carousel lathes: Ideal for machining large, heavy workpieces, offering exceptional stability and precision.

With this diversity in our machinery, we are able to meet the wide range of requirements of our customers, providing products and services of the highest quality. Our advanced CNC machines, combined with the extensive experience of our team, allow us to continually raise standards in the machining industry.

CNC Lathe: The Heart of Innovation

The CNC lathe is truly the heart of our innovations. This advanced machine is crucial for precision machining of a wide variety of materials, from metals to plastics. Thanks to its numerical control, the CNC lathe allows complex shapes and patterns to be made with a precision that cannot be achieved with traditional lathes. It offers unparalleled accuracy, allowing even the most complex parts to be made with tolerances measured in microns. Compared to conventional lathes, CNC lathes are distinguished by significantly higher efficiency and reduced production time, which is crucial in the dynamic world of modern manufacturing.

Our CNC lathes are equipped with advanced features such as automatic workpiece reversal, which enables two-sided machining without manual intervention, greatly increasing productivity. In addition, flexibility in programming allows us to quickly adapt to individual customer needs and realize complex custom projects. In our machinery, CNC lathes are the foundation that allows us not only to maintain the high quality of our products, but also to constantly strive for innovation and development, making us a leader in the machining industry.

Advanced technologies and their impact on the quality of manufactured parts

At CNC PARTNER, we firmly believe that advanced technologies are the key to producing parts of the highest quality. In our machine park, driven tool machines and advanced CNC machining centers play a particularly important role. Thanks to them, we are able to perform complex machining operations, such as drilling, threading and milling, in a single machine setup. This not only increases the precision of workpieces, but also significantly reduces production time, which is essential in a rapidly changing production environment.

The use of driven tools enables us to realize complex geometries and designs that would be impossible with traditional methods. Our CNC machining centers, equipped with the latest software and automation, allow very precise repeatability of parts, minimizing the risk of errors and increasing the overall quality of manufactured parts. As a result, our products are used in demanding sectors such as aviation, automotive and medicine, where absolute precision and reliability are required.

We are constantly investing in new technologies and training our staff to stay abreast of the latest trends and innovations in the industry. We are convinced that our commitment to advanced technologies directly translates into high quality and efficiency in our services, allowing us to not only meet but often exceed our customers’ expectations.

The Future of CNC Machining and Development Plan

Invariably, we look to the future of CNC machining with great enthusiasm, which is full of innovation and unlimited possibilities. Our development plan focuses on implementing the latest CNC technologies that will allow us to maintain our leadership position in the industry. We are aware that upcoming innovations, such as greater integration with artificial intelligence and automation technologies, will be crucial to our continued growth. Therefore, we plan to invest in advanced control systems and software that will increase the efficiency, precision and capabilities of our CNC machines.

One of our main goals is also to expand our competence in machining materials with high machining difficulty, which requires innovative cutting strategies and specialized tools. We also plan to develop our CNC machining centers to make them even more versatile and flexible in handling a wide variety of projects. This combination of technological innovation and our experience and expertise will allow us to handle even more complex and demanding tasks for our customers.

We aim to be at the forefront of the CNC machining revolution, constantly improving our processes and techniques. Our vision for the future is not only to develop machines and technology, but also to invest in our employees, whose skills and knowledge are the foundation of our success. We believe that our commitment to continuous development and adaptation to the changing world of CNC technology will allow us to reach new levels of innovation and excellence in manufacturing.

CNC PARTNER – this is just the beginning.

At CNC PARTNER, we play a key role in the development of CNC technology, continually investing in innovation and improvement of machining techniques. Our commitment to the latest technologies, including intelligent control systems and automation, directly affects the quality and precision of our products, allowing us to not only meet current market demands, but also to shape the future of the industry. Innovation is the cornerstone of our growth strategy, opening up new horizons of opportunity. We are committed to the continuous development and improvement of our manufacturing processes, allowing us not only to raise industry standards, but also to proudly influence its dynamic development.